86-18059874023

silinzhang@betalentcarbide.com

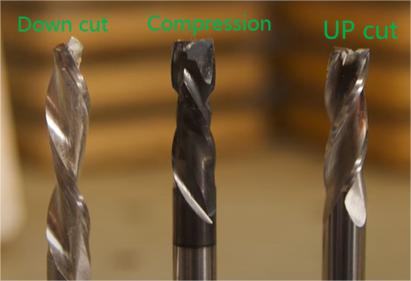

These three end mills are popular in woodworking. The differences among them are as follows:

1. The flute or chip pocket spiral direction. Up-cut end mill has upward going spiral when it rotates, Down cut end mill has downward going direction spiral, compression end mills have upward and downward directions.

2. Surface edge after maching is different. The upper edge is clean and the bottom edge is coarse by down cut end mills while it is coarse upper edge and clean bottom by up cut end mills, and by compression end mills, both upper and bottom cut edge is clean.

3. Tips: up-cut is good for plunging, plastics, and thick materials, down cut end mills is good for hard or figured woods.