Carbide end mill is one of the most widely used milling cutters in CNC machine tools. There are cutting blades on the cylindrical surface and end face, mainly used for plane milling, groove milling, step surface milling, and profile milling. Compared with HSS end mill, carbide end mill cutter performs much better in high-speed, high-efficiency, and high-temperature milling, the heat resistance can reach 1000 ℃(HSS 600-650℃), wear resistance is 15-20 times that of HSS, and cutting speed can be 4-10 times that of HSS end mill.

Betalent carbide focus on carbide end mill cutters, according to the different combination of carbide grades and coatings, standard carbide end mills can be classified to be 5 types, there are end mills for 45HRC and below, 50HRC, 55HRC, 60HRC and above, and end mills for aluminum alloy. If classified by workpiece materials, Betalent has a series of carbide end mill cutters for aluminum, end mills for titanium, end mills for stainless steel, end mills for woodworking, end mills for super hard metals.

Betalent manufactures a series of high-performance carbide end mills, including carbide end mills for aluminum, end mill for stainless steel, and so on. If you need to know our carbide end mill price, please feel free to contact us.

| Grade | Co% | Grain Size | Density (g/cm) | Hardness(HRA) | TRS N/mm2 | Application |

| BT45 | 10 | 0.8 | 14.4 | 91.7 | 4400 | For general drill bit, end mill and punching die |

| BT50 | 10 | 0.6 | 14.45 | 92.3 | 4400 | For general drill bit, end mill machining titanium alloy, stainless steel and gray cast iron. |

| BT55 | 12 | 0.4 | 14.1 | 92.6 | 4600 | For cutting tools machining titanium alloy, heat resistant alloy, stainless steel, quenched steel(HRC55-58), gray cast iron. |

| BT60 | 9 | 0.2 | 14.35 | 94.1 | 5000 | For cutting tools machining quenched materials (HRC60-65), hardwood and high polishing cutters. Finish machining 316L stainless steel. |

Betalent Carbide has advantages in custom end mills.

Material custom: Betalent has a series of different carbide grades for cutting tools for your options. If no one can meet your requirement, you can custom your special carbide grade from us, our engineer team can support you to develop one new grade for your special requirement.

Size custom: We accept size custom, both metric size and inch size.

Geometry custom: You can custom the unique geometry of end mills by detailed drawing.

Custom application: If you don't have a detailed drawing, you can give us the detailed size of the machining result you want to gain, the workpiece material, the groove you want to get or describe the current problem you have, our engineer can help you to custom end mills can fit your needs.

Choose the right type of end. A flat end mill has a square end, suitable for coarse milling, or fine milling of a small flat surface or profile. Corner radius end mill breaks the sharp end, can be applied for coarse milling, or fine milling of the flat surface and small chamfer. Ball end mill has a ball nose end, can be used for surface semi-finishing milling and finishing milling, small diameter ball end mill can fine mill steep or straight wall, small chamfer and irregular profile. Choose corner radius end mill or ball end mill? If the workpiece is large and has a less small concave area, the surface is relatively flat with a small change, choose the corner radius end mill. If there are small concave areas, choose the ball end mill. Profile end mills include chamfering end mill, T shape end mills, thread milling cutter, inner R cutter for special shape milling.

Choose the right flute number. Commonly, there are 2 flutes,3 flutes,4flutes,6 flutes end mills. The more the number of flutes,2 flute end mill suitable for key groove. 3 flute end mill are most applied for aluminum alloy milling, 4 flute is most general, and 6 flute end mill is for fine milling. The more flutes, the more stable cutting(and tougher) but the shallower chip pocket(Less efficient chip removing), we need to balance the two.

Choose the right carbide grade and coating. Betalent offers standard combinations for different applications, you are not required to do this selection. Please communicate with Betalent sales persons what you need to mill, they will offer the solution.

Carbide end mills are used for milling plane, steps, grooves, forming surface and cutting workpiece.

Carbide end mills are made of micro grain size tungsten carbide and cobalt.

Most common end mills are square end mills, corner radius end mills, ball end mills for cutting workpiece of which hardness ranges from 30HRC to 65HRC.

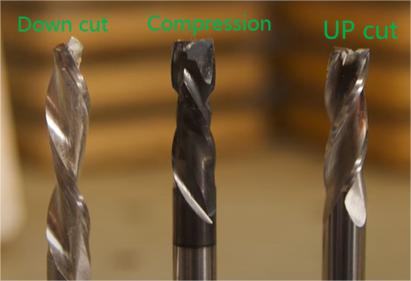

These three end mills are popular in woodworking. The differences among them are as follows:

1. The flute or chip pocket spiral direction. Up-cut end mill has upward going spiral when it rotates, Down cut end mill has downward going direction spiral, compression end mills have upward and downward directions.

2. Surface edge after maching is different. The upper edge is clean and the bottom edge is coarse by down cut end mills while it is coarse upper edge and clean bottom by up cut end mills, and by compression end mills, both upper and bottom cut edge is clean.

3. Tips: up-cut is good for plunging, plastics, and thick materials, down cut end mills is good for hard or figured woods.