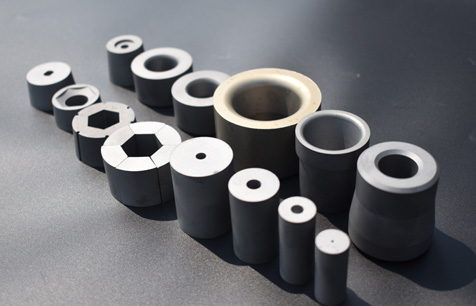

Xiamen Betalent Carbide Co., Ltd is a professional carbide product inc, focusing on designing, producing, and selling cemented carbide materials and cemented carbide products. It is located in Xiamen, Dongguan, Ganzhou of China, head office and main plant is in Xiamen, plants covering an area over 10000M2, employee number is 150, among them there is a 15 technician team continually research and develop new items and offer professional technology back up to sales staff, a 20-person quality control team. Betalent carbide factory has advanced facilities and inspection instruments, offers carbide products to the middle to the high-end market.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt