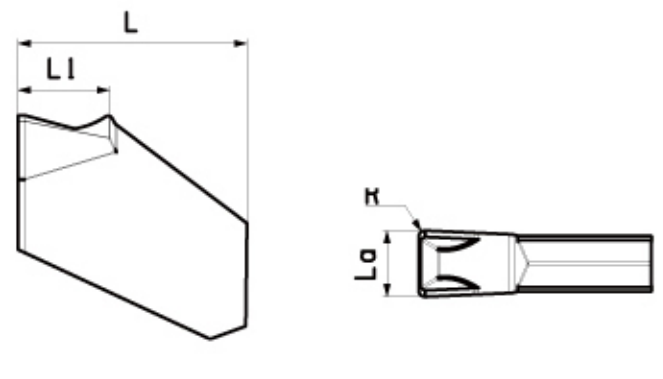

Parting and grooving inserts are inserts for cylinder parting and grooving, including to the outer circular, the inner hole groove, the cutter withdrawal groove, and the end face groove.

The groove shape includes the narrow, wide, and forming groove. The process features of these inserts are as follows:

1)There are one main cutting edge and two auxiliary cutting edges involved in three-dimensional cutting at the same time. The feed is small, cutting thickness is thin, the unit cutting force is increased, total cutting force and power consumption are large, the cutting heat is high, heat dissipation is poor, and the cutting temperature is high.

2)The cutting speed changes constantly in the process of machining, especially when parting, the cutting speed changes from maximum to zero.

3)As the workpiece rotates, the cutter cuts in continuously. In fact, the Archimedes spiral surface is formed on the workpiece surface. As a result, the actual front angle and back angle are constantly changing, making the process more complicated.

4)Due to the narrow width of the tool, relative hanging elongation, poor rigidity of the tool, easy to vibrate.

Betalent carbide parting and grooving inserts are designed and manufactured considered above factors and are belong to high-level quality. The standard stock mainly includes the following three categories.

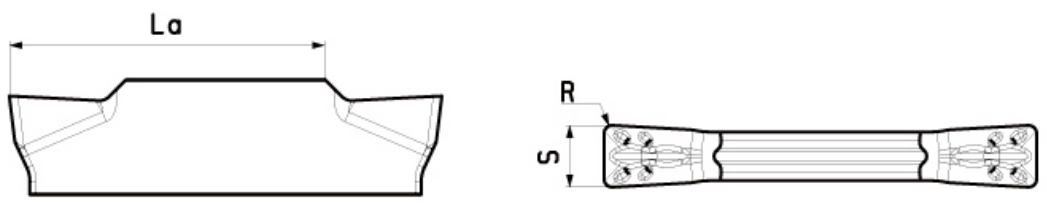

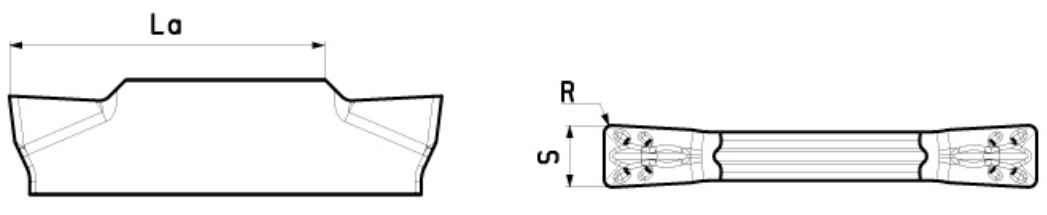

| Model code | S | R | La |

| MGMN200-M | 2 | 2 | 14.5 |

| MGMN250-M | 2.5 | 0.2 | 17 |

| MGMN300-M | 3 | 0.4 | 17 |

| MGMN400-M | 4 | 0.4 | 22 |

| MGMN500-M | 5 | 0.8 | 22 |

| MGMN600-M | 6 | 0.8 | 22 |

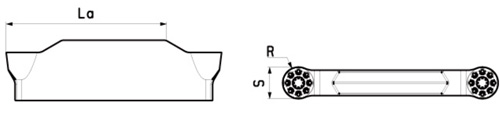

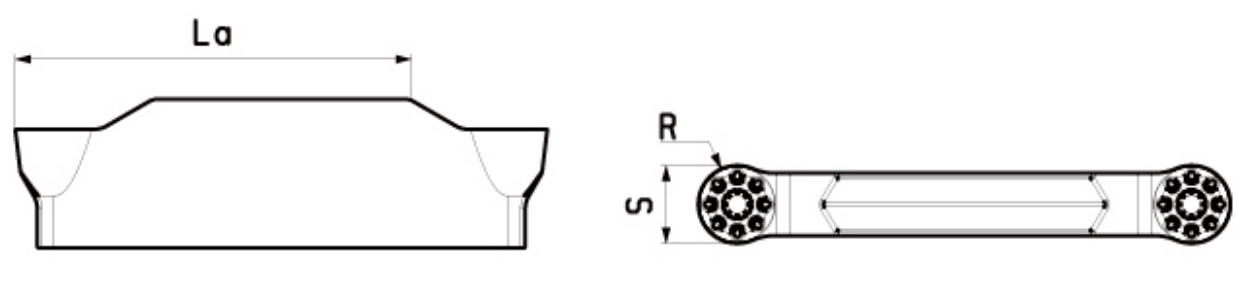

| Model code | S | R | La |

| MRMN250-M | 2.5 | 1.25 | 17 |

| MRMN300-M | 3 | 1.5 | 17 |

| MRMN400-M | 40 | 2 | 21 |

| MRMN500-M | 5 | 2.5 | 20 |

| MRMN600-M | 6 | 3 | 19 |

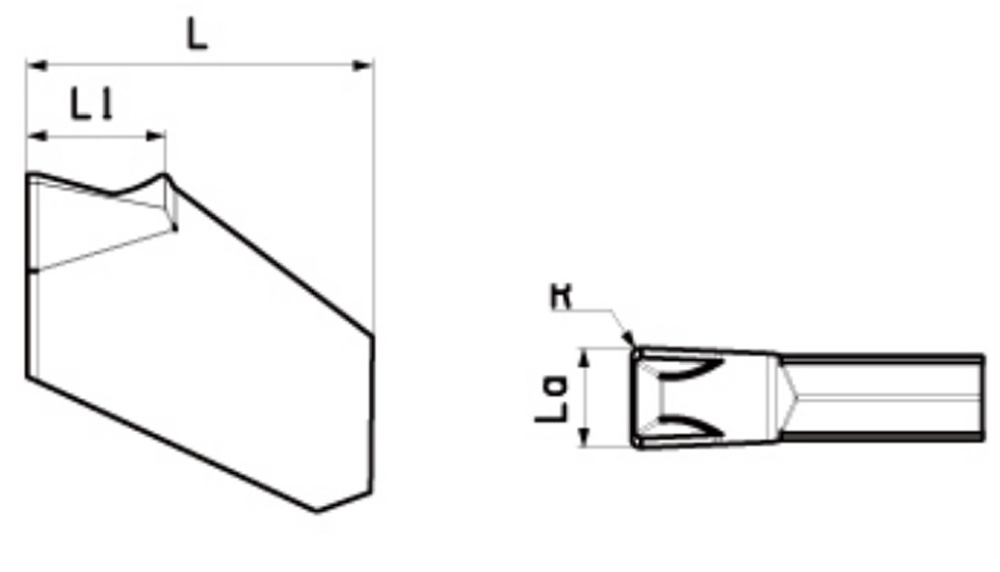

Parting and grooving inserts are inserts for cylinder parting and grooving, including to the outer circular, the inner hole groove, the cutter withdrawal groove, and the end face groove.

The groove shape includes the narrow, wide, and forming groove. The process features of these inserts are as follows:

1)There are one main cutting edge and two auxiliary cutting edges involved in three-dimensional cutting at the same time. The feed is small, cutting thickness is thin, the unit cutting force is increased, total cutting force and power consumption are large, the cutting heat is high, heat dissipation is poor, and the cutting temperature is high.

2)The cutting speed changes constantly in the process of machining, especially when parting, the cutting speed changes from maximum to zero.

3)As the workpiece rotates, the cutter cuts in continuously. In fact, the Archimedes spiral surface is formed on the workpiece surface. As a result, the actual front angle and back angle are constantly changing, making the process more complicated.

4)Due to the narrow width of the tool, relative hanging elongation, poor rigidity of the tool, easy to vibrate.

Betalent carbide parting and grooving inserts are designed and manufactured considered above factors and are belong to high-level quality. The standard stock mainly includes the following three categories.

| Model code | S | R | La |

| MGMN200-M | 2 | 2 | 14.5 |

| MGMN250-M | 2.5 | 0.2 | 17 |

| MGMN300-M | 3 | 0.4 | 17 |

| MGMN400-M | 4 | 0.4 | 22 |

| MGMN500-M | 5 | 0.8 | 22 |

| MGMN600-M | 6 | 0.8 | 22 |

| Model code | S | R | La |

| MRMN250-M | 2.5 | 1.25 | 17 |

| MRMN300-M | 3 | 1.5 | 17 |

| MRMN400-M | 40 | 2 | 21 |

| MRMN500-M | 5 | 2.5 | 20 |

| MRMN600-M | 6 | 3 | 19 |